Welcome to Shourya Supercritical Technology

We represent SHOURYA SUPERCRITICAL TECHNOLOGY (earlier known as Super C Essence And Extracts), a leading manufacturer of supercritical fluid extraction plants (pilot to commercial scale) as well as essential oils and extracts.

Manufacturing Excellence

Established in 2005, we are leaders in supercritical extraction technology with indigenously developed solutions.

Premium Essential Oils

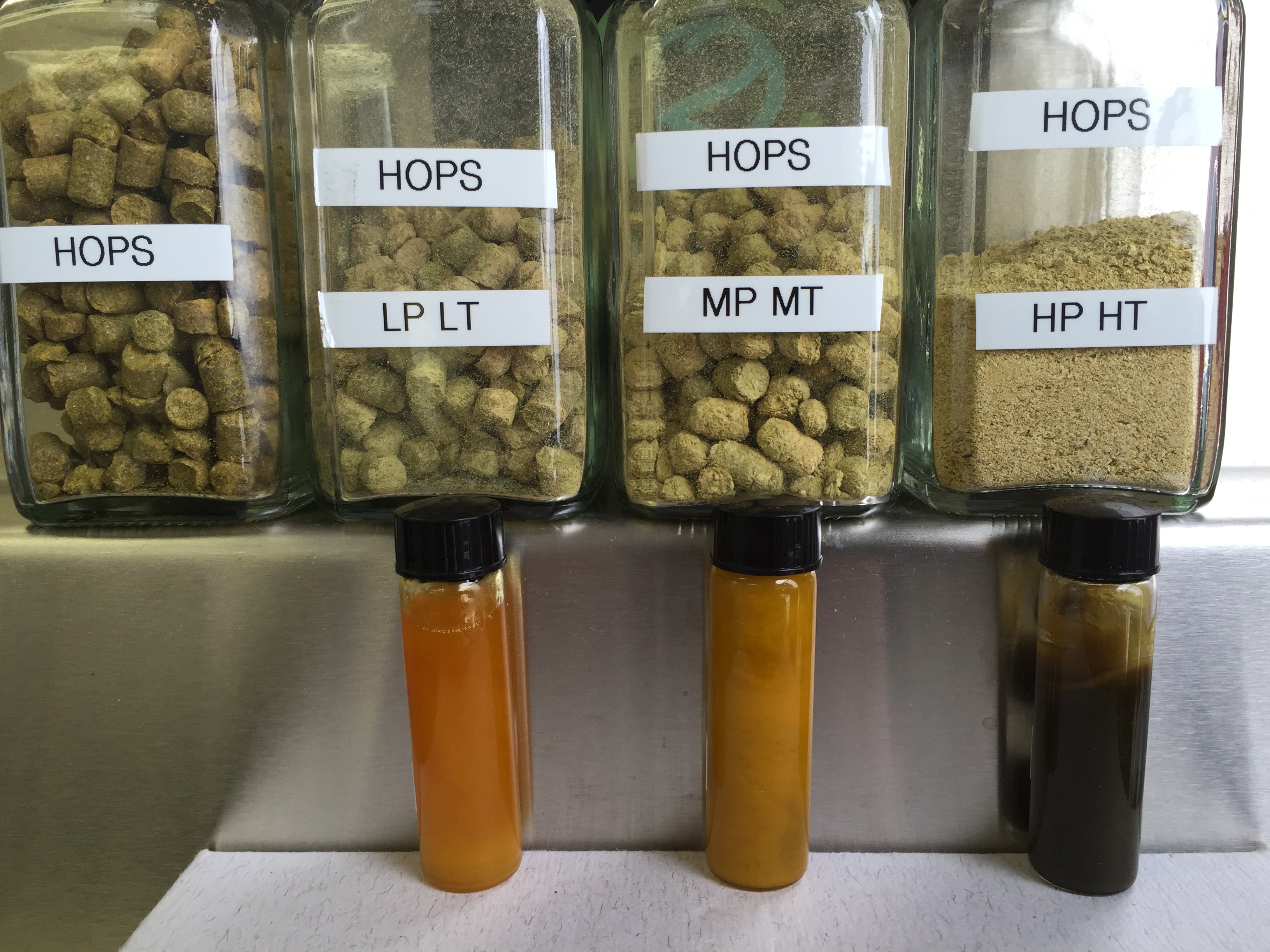

100% pure, natural oils and extracts from excellent raw materials using advanced SCFE technology.

Advanced Technology

Manual, semi-automatic, and fully automated configurations with the lowest process cost in the industry.

Our Commitment

Combination of traditional herbal knowledge and modern extraction technology. Our plants are designed for accurate monitoring and control, ensuring high consistency and superior quality products.